Freedom in Metal AM Development & Production

A3DM TECHNOLOGIES & AMAZEMET

A3DM TECHNOLOGIES & AMAZEMET

Technology, devices, knowledge, collaboration…Technology, devices, knowledge, collaboration… We have everything for Metal Additive Manufacturing, new material development, special powder atomization, printed parts postprocessing.

A Revolutionary Approach to Material Research & Powder Production

AMAZEMET’s technology is a game-changer for material research and metal additive manufacturing. It revived ultrasonic atomization to revolutionize the approach to powder production and material development, meeting the demands of modern researches and industries focused on innovation and efficiency.

The technology, unlike gas atomization systems, uses ultrasonic vibration for metal atomization. At its core, this technology utilizes high-frequency sound waves to create small particles from a liquid. It’s quite similar to the ultrasonic humidifiers, where a fine mist is produced from water. The same principle applies here, but instead of water, we use molten metals like steel, titanium, or other high-temperature alloys. Metal is poured or melted directly on the vibrating part resulting with tiny droplets being ejected from the surface. Droplets solidify in surrounding inert gas atmosphere forming powder particles.

The result are highly spherical metal powders with narrow particle size distribution – up to 80% is good to use in desired processes.

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

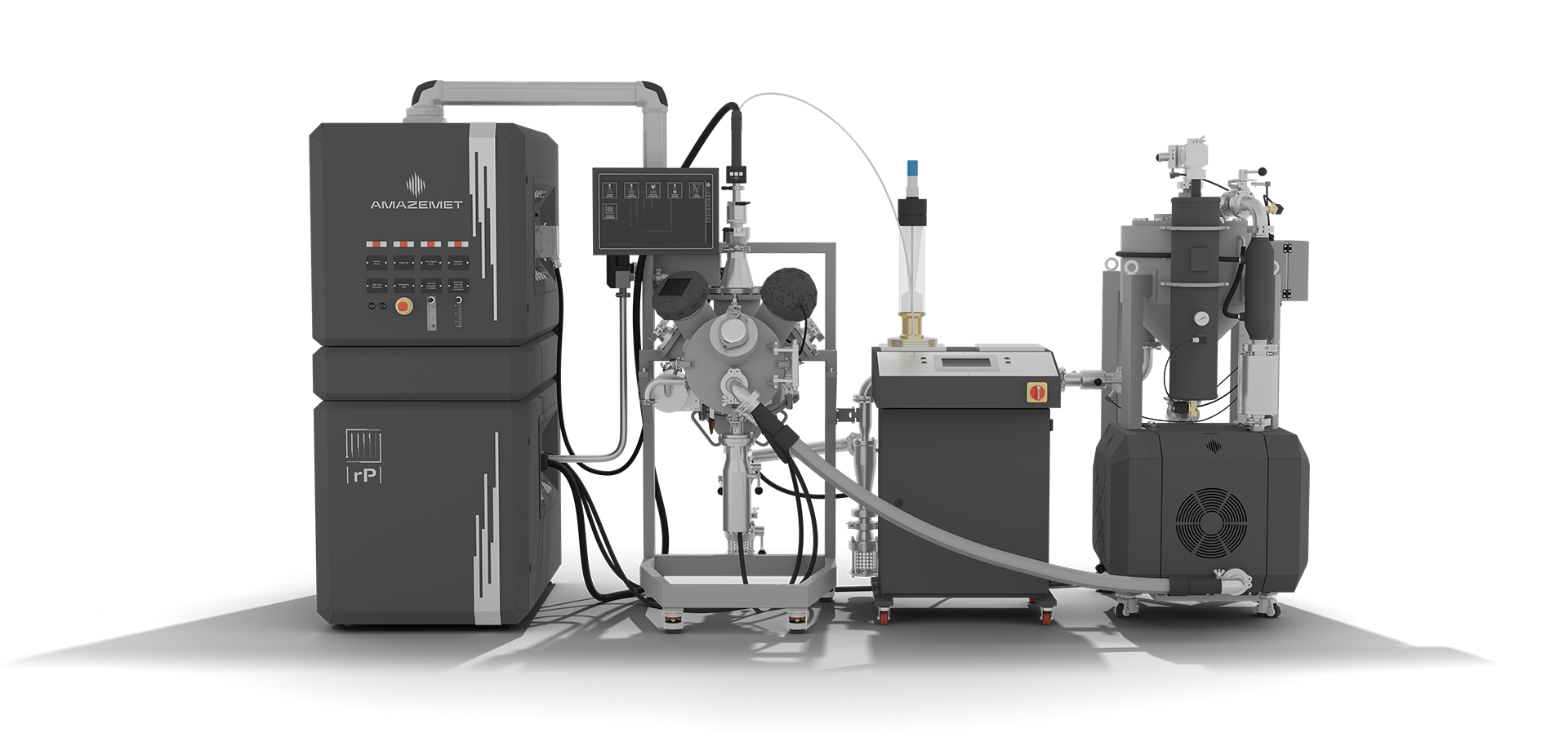

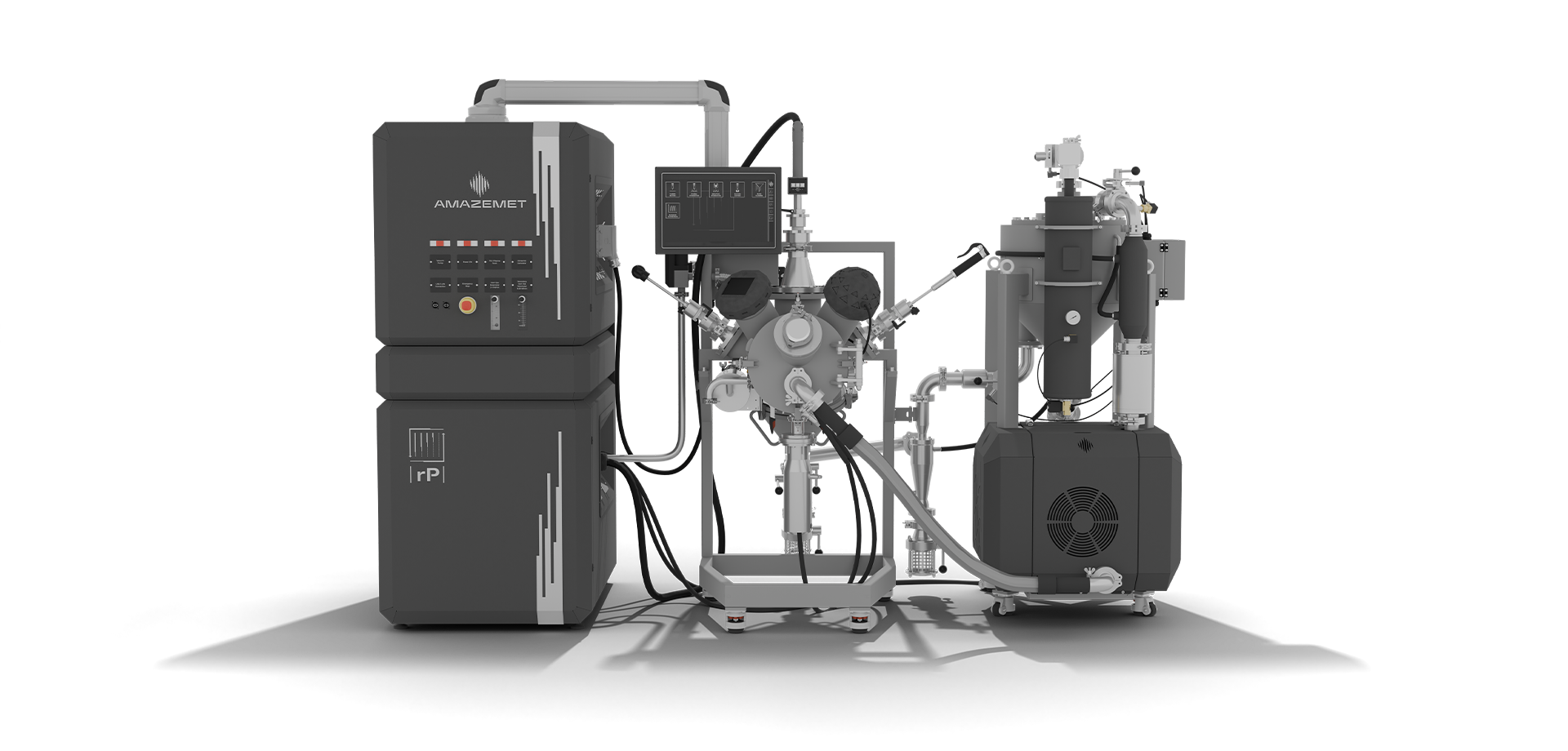

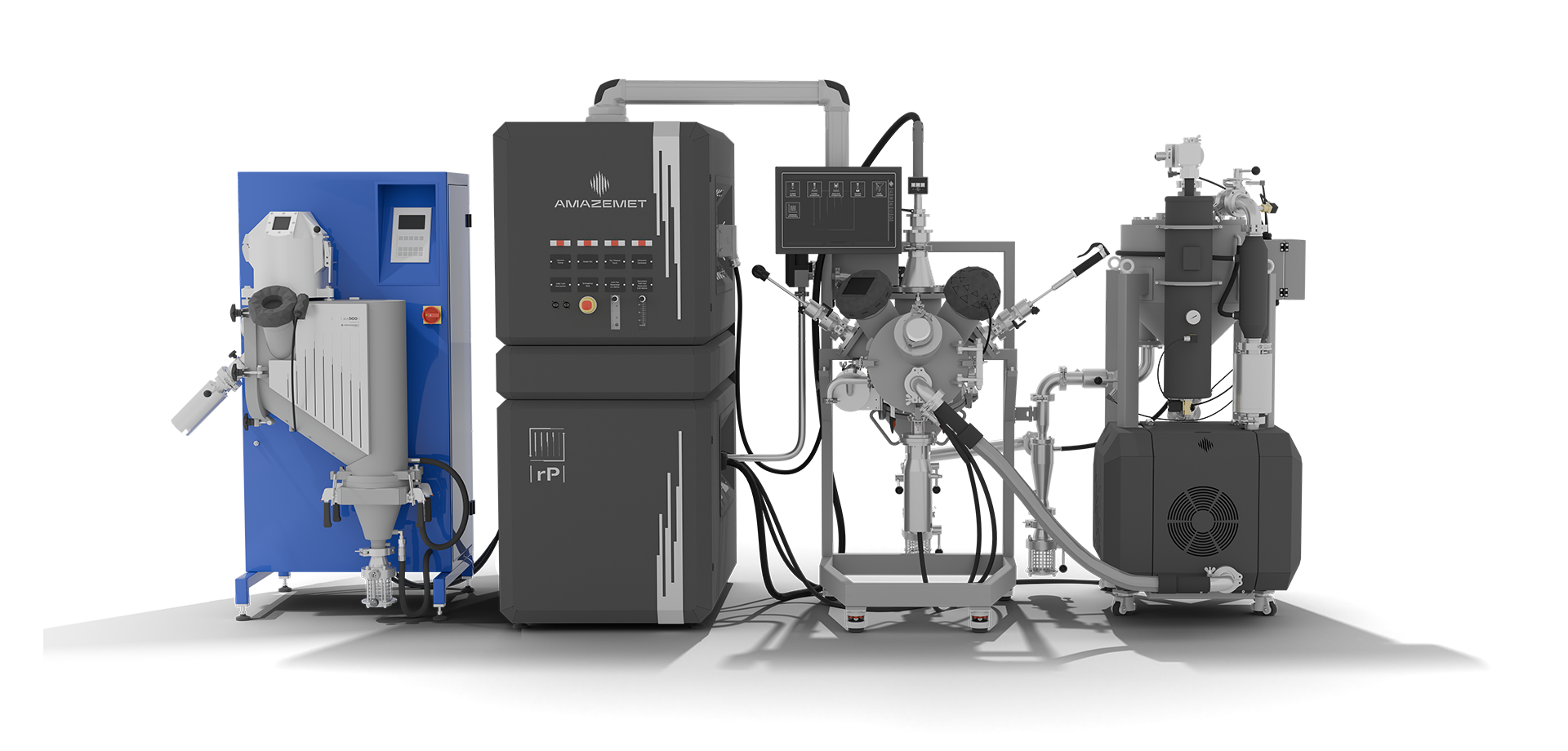

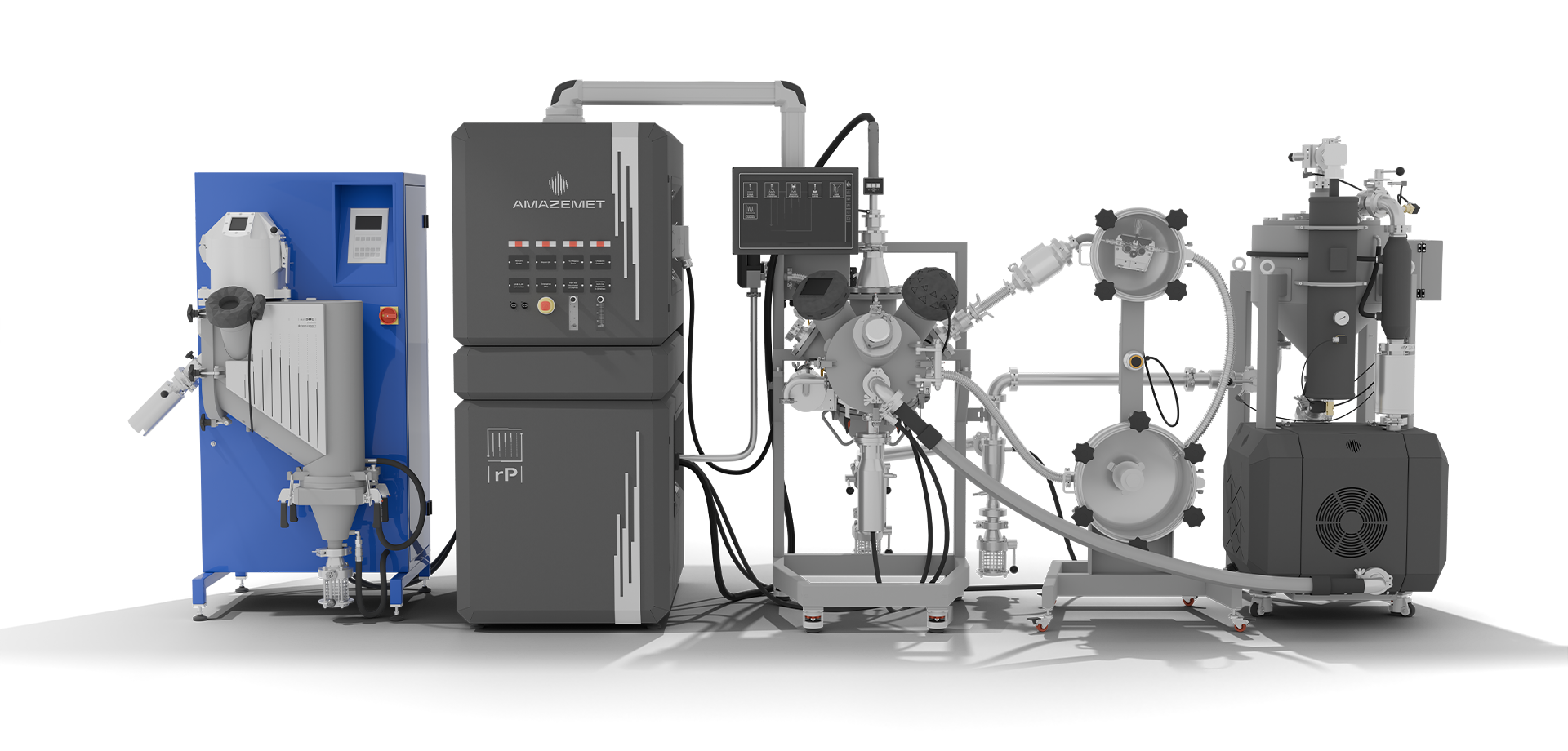

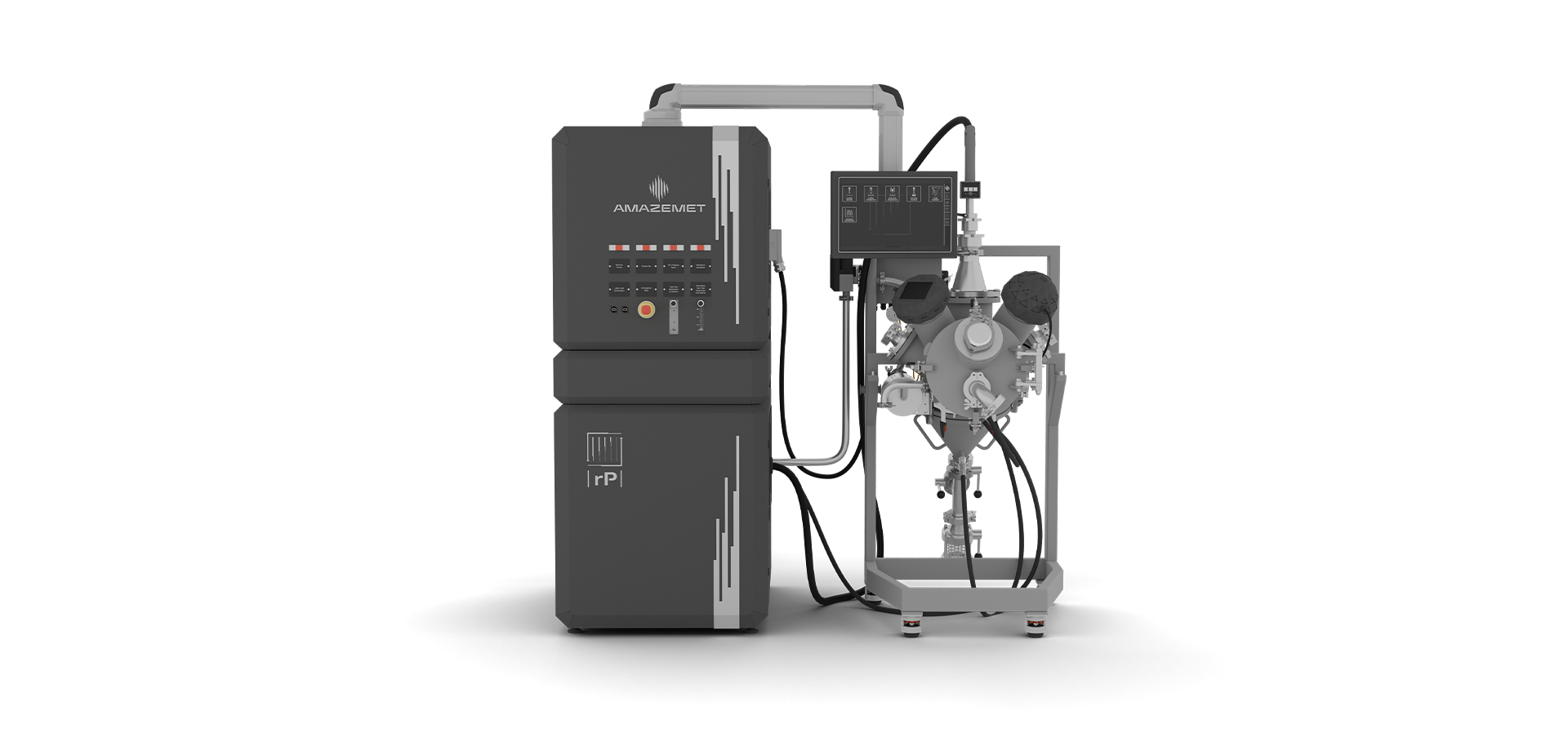

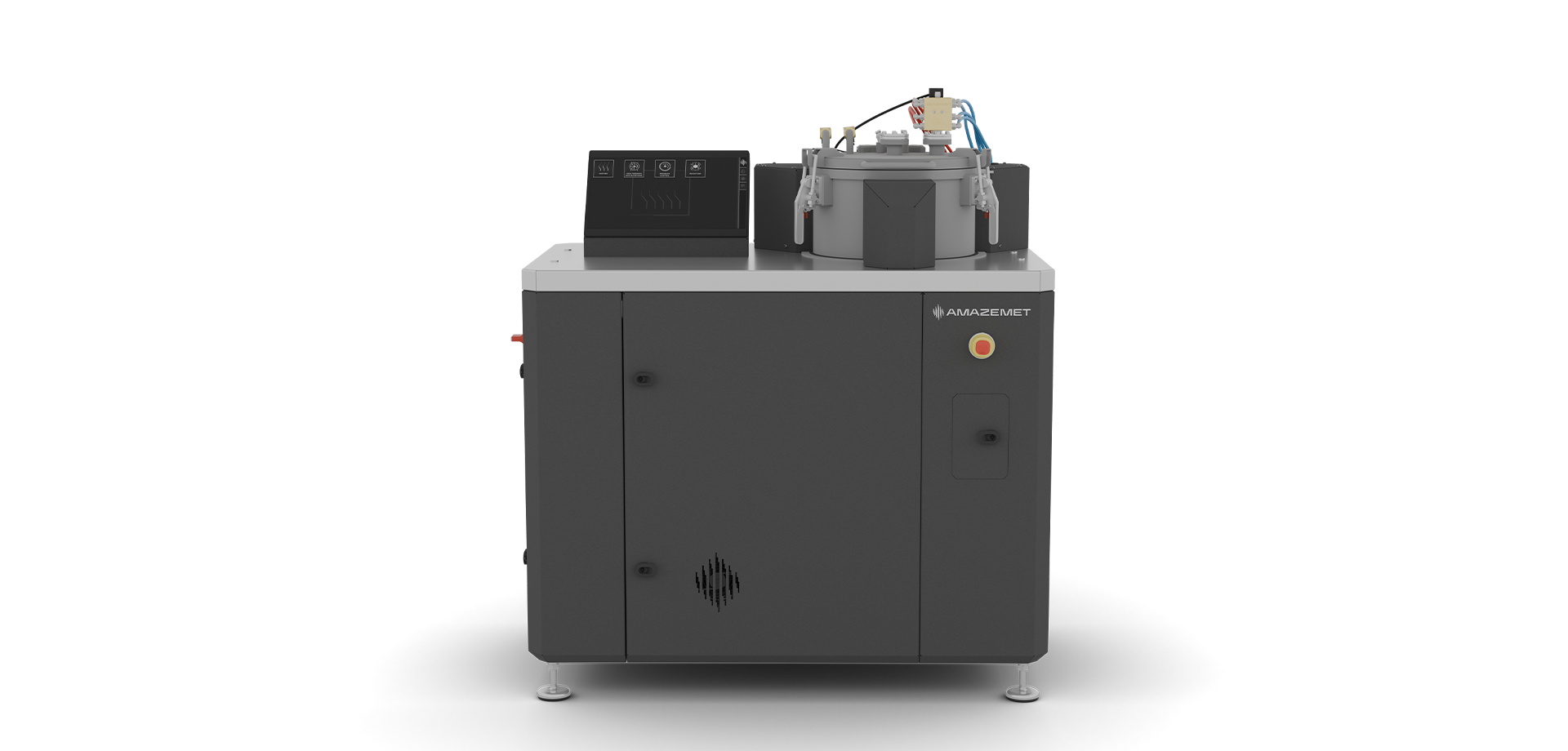

Discover some of the predefined versions of our devices:

LABORATORY SCALE UNITS FOR RESEARCHERS

We provide and develop advanced ultrasonic atomization devices for tailored powder manufacturing and compact high-vacuum furnaces for post-processing and heat-treatment applications. Laboratory-scale solutions like rePOWDER and inFURNER support leading researchers worldwide in Additive Manufacturing and beyond.

This periodic tables shows the elements we already processed with rePOWDER, what makes it the most versatile processing platform on the market.

STRONG FOUNDATION OF OUR SOLUTIONS

Strong Patents Behind AMAZEMET’s Technology

Our solutions, including the groundbreaking rePOWDER ultrasonic atomizer, are based on patented technology, which protects their uniqueness and reliability. Our portfolio of over 12 patents worldwide, continues to solidify our position at the forefront of technology. By securing intellectual property, we provide our clients with innovative and trusted technologies that drive progress in industries such as additive manufacturing, powder metallurgy, recycling and more.

OUR CUSTOMERS

Trusted by Innovators Worldwide

AMAZEMET is proud to collaborate with a diverse range of clients who trust our cutting-edge solutions to advance their projects. Explore some of our key partnerships with industry leaders and innovators driving progress in additive manufacturing and materials science.

Freemelt ONE & AMAZEMET’s rePOWDER Ultrasonic Atomizer

Colibrium Additive at Formnext 2024 | Jose Greses Exclusively For AMAZEMET

TU Darmstadt & AMAZEMET Magnetocalorics Research

AMAZEMET & f3nice | Matteo Vanazzi | Sustainable Innovation with rePOWDER

COLLABORATION

OUR SCIENTIFIC PARTNERS

Our collaborations drive innovation and push the boundaries of materials science. Meet AMAZEMET’s trusted academic partners who play a key role in advancing our research and technological developments. Together, we shape the future of additive manufacturing and beyond.

A3DM TECHNOLOGIES

A3DM Technologies provides research and manufacturing solutions for thermal processing of spherical metal and ceramic powders, supporting both academic and government laboratory programs. Additional A3DM expertise also includes applications in high-enthalpy plasma platforms for ground-based qualification of thermal protection materials required for hypersonic flight and orbital re-entry vehicles.

Founding A3DM Technologies in 1996 as one of the first Rapid Prototyping Bureau Service companies, Steven Adler has contributed to the development of numerous OEM additive manufacturing technologies for precision components. Steven’s expertise in powder metallurgy targets precious and refractory metal applications for additive manufacturing.

Steven Adler

USA 2025 EVENTS

MEET US THERE

These events are the perfect opportunity to learn more about our devices, discuss research challenges, and explore collaboration possibilities in AM and materials science. Visit our booth, meet our team, and discover how AMAZEMET’s solutions can accelerate your projects. Schedule a meeting in advance to ensure a dedicated time for in-depth discussions.